From its founding in 2015, Hanway now reaches the 2025 mark of its first decade—a journey defined by relentless development—unwavering in its mission: to lead the manufacturing of digital printing solutions for the packaging industry.

Ten years ago, "digital" in the packaging industry was largely defined by multi-pass systems or UV inkjet. These multi-pass systems couldn't meet industrial speed demands, while UV was plagued by short printhead life, high ink costs, and a critical barrier: it was unsuitable for food packaging. The industry’s imagination was limited.

At this technological crossroads, Hanway made a bold decision. They aimed for the industry's recognized peak: Single Pass. According to Leo Peng, Vice General Manager (R&D Director), Hanway’s identity was "industrial-grade" from its inception. The company rooted itself directly in Single Pass technology and, crucially, committed to the water-based inkjet path—the most challenging peak to climb.

At the time, water-based Single Pass for corrugated was an unexplored "white space." Hanway was on the same starting line as the established European and American giants. Yet, this "from-scratch" challenge only solidified the team's conviction. As General Manager Johnson Tan declared, "After comprehensive market research, we were certain: water-based is the future of packaging."

The Hanway team saw that this combination precisely solved the industry's core demands. Single Pass offered the high-speed, on-demand capabilities needed for flexible, industrial-scale production. Furthermore, water-based ink provided superior stability in downstream processes like gluing and finishing—no cracking, no adhesion problems. It was also a lower-cost, eco-friendly solution that unlocked the massive, high-value market for food-grade packaging.

"It was, in essence, a choice for a green, sustainable printing model," explained Jon Jing, General Manager's Assistant. "Choosing water-based was choosing to 'go green.' This wasn't just a business decision; it was a responsible choice for the planet and one that truly benefits the industry's long-term future."

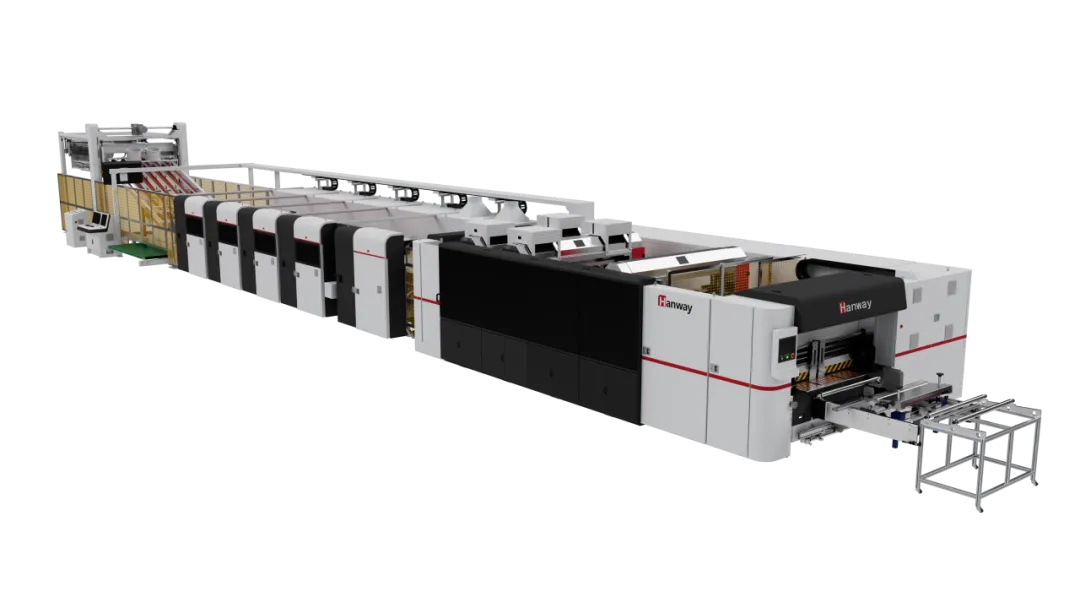

By understanding the industry's real demand for "Speed + Flexibility + Sustainability," Hanway delivered the solution: the Glory 1604, a high-speed, water-based digital inkjet Single Pass printer. At a revolutionary 150 m/min, it gave digital printing true industrial-scale production capability for the first time.

"You see the light grey gradient on this appliance box," R&D Director Leo Peng explained, holding a sample, "and the intricate details in this watch graphic. The rich color and fine detail that digital can achieve are things traditional printing struggles with." He noted that as the technology iterated, the Glory series also became optimized for printing large, solid-color blocks, meeting the needs of most coated board customers.

"We are relentlessly optimizing around customer pain points," Peng continued. "That means cutting changeover times to mere seconds, achieving seamless job-to-job switching for same-sized boards, and upgrading resolution from 600DPI to 1200DPI with registration accuracy within ±1 pixel. It’s all about boosting the customer’s efficiency and quality."

Critically, the Glory 1604 was never just a standalone printer; it was conceived as an "innovative, integrated industrial digital line." Its modular design gave it powerful extensibility, allowing for the in-line integration of drying, varnish, and stacking modules. When paired with Hanway's proprietary MES, it could connect seamlessly with a customer's existing ERP system, enabling intelligent, end-to-end management of orders, scheduling, and quality control.

From that moment, Hanway's Single Pass products have always been anchored to two core principles: "solving customer order pain points" and "meeting industrial batch production needs." "Technology must ultimately be grounded in the customer's real-world production," concluded GM Johnson Tan. "It has to help them improve quality, reduce costs, and increase efficiency. That is the true path to profitability and digital transformation."

As China's first truly industrial-grade digital inkjet printer for corrugated, the Glory 1604's launch was a landmark. It not only filled the "white space" for high-speed, water-based inkjet in packaging but also established Hanway as a major force, laying the cornerstone for its global expansion.

"In many ways, our customers are our teachers," Assistant GM Jon Jing admitted. He explained that customers, through their own ingenuity, often push digital's advantages to the extreme. "For example, many of our overseas clients are masters of elegant, simple design. They use minimal color palettes to create classic, timeless packaging. This 'less is more' philosophy showed us a new dimension of digital's potential."

For Hanway, "customer service" has never been a one-way street; it's a mutual process of learning and growth. Customers are on the front lines. They know what end-brands demand and what real-world production pain points look like. Every experiment, every innovation a customer tries on a Hanway machine provides the most vivid, practical feedback possible, guiding Hanway's R&D and saving the company from "building a car behind closed doors."

It is precisely this unwavering "customer-driven" focus that has pushed Hanway's Single Pass equipment to constantly evolve, resulting in a comprehensive and diverse product matrix. Building on the Glory 1604, the family expanded to include the Glory 1606, the new 1200DPI Glory 160X HD, the best-selling wide-format Glory 2504, and the new high-efficiency Elite 2504.

Looking back, how did Hanway transform from a "digital newborn" into a key player in the global market? The answer lies in a decade of relentless R&D, a precise and agile response to real-world customer demands, and the unwavering mission of a team dedicated to reshaping the industry with water-based Single Pass technology.

Hanway's growth was never a solo fight. It has always been a shared journey, a story of mutual success with its customers. As Hanway looks to its next decade, it does so with the same spirit: ready to march forward, side-by-side, into a new digital era.

Company :Shenzhen Hanglory Digital Printing Group Co., Ltd

Phone:0755-23080896 / 0755-23062862

Fax:0755-23217841

Address:HanGlory Headquarters (No. 28, Gaoke Avenue, Baolong Subdistrict, Longgang District, Shenzhen, China)

E-mail :info@hanglorygroup.com

Are you ready? Then contact us