A long-standing challenge in the textile industry has finally been overcome. The GEEHONG ROCKET Single Pass Hybrid Digital Textile Printer has achieved a major breakthrough: successful high-speed printing on notoriously difficult knitted four-way stretch fabric, even with complex, sensitive gradient color patterns. This industry-first capability is already fully operational and delivering results for our customer, Dachangde Digital.

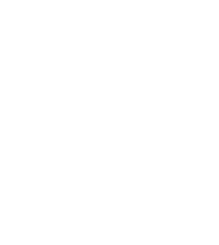

"What I'm holding is a print fabric that was once considered impossible to produce at high speed," explained a GEEHONG technician from the production floor at Dachangde Digital. "This is a 95% Sirospun rayon with 5% spandex. At only 140g, it’s incredibly lightweight and elastic in all directions, like a rubber band. On top of that, the design is a full-coverage, dark-to-light gradient—adding another layer of extreme difficulty."

The Challenge: Why High-Speed Printing on Stretch Knits Was a Nightmare

While printing on four-way stretch fabric is feasible on slower, scanning-type printers, the low speed allows operators to manually manage fabric tension and control issues like edge curling.

However, on high-speed Single Pass systems, the technical difficulty increases exponentially:

· Precision Tension Control: The fabric's elasticity requires an exceptionally precise tension management system that is nearly impossible to maintain at high speeds.

· Edge Curling & Instability: Any slight inconsistency in tension is instantly amplified, causing the fabric to stretch, curl, or warp too quickly for manual intervention.

· Critical Defects: This instability leads directly to fatal printing flaws like ghosting and misalignment, resulting in massive waste and making industrial-scale production unviable.

The GEEHONG Solution: Breakthrough Technology for Flawless Results

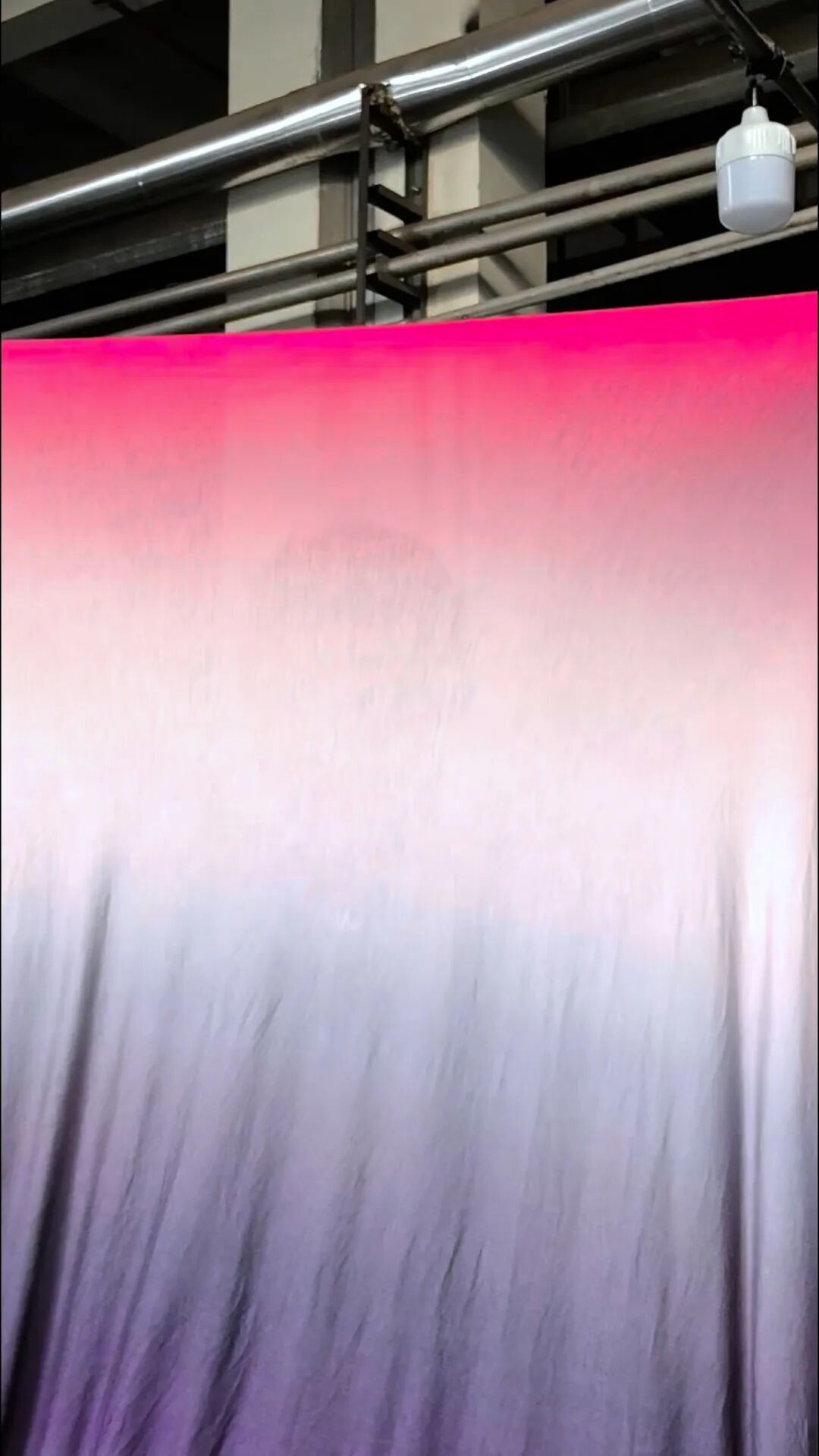

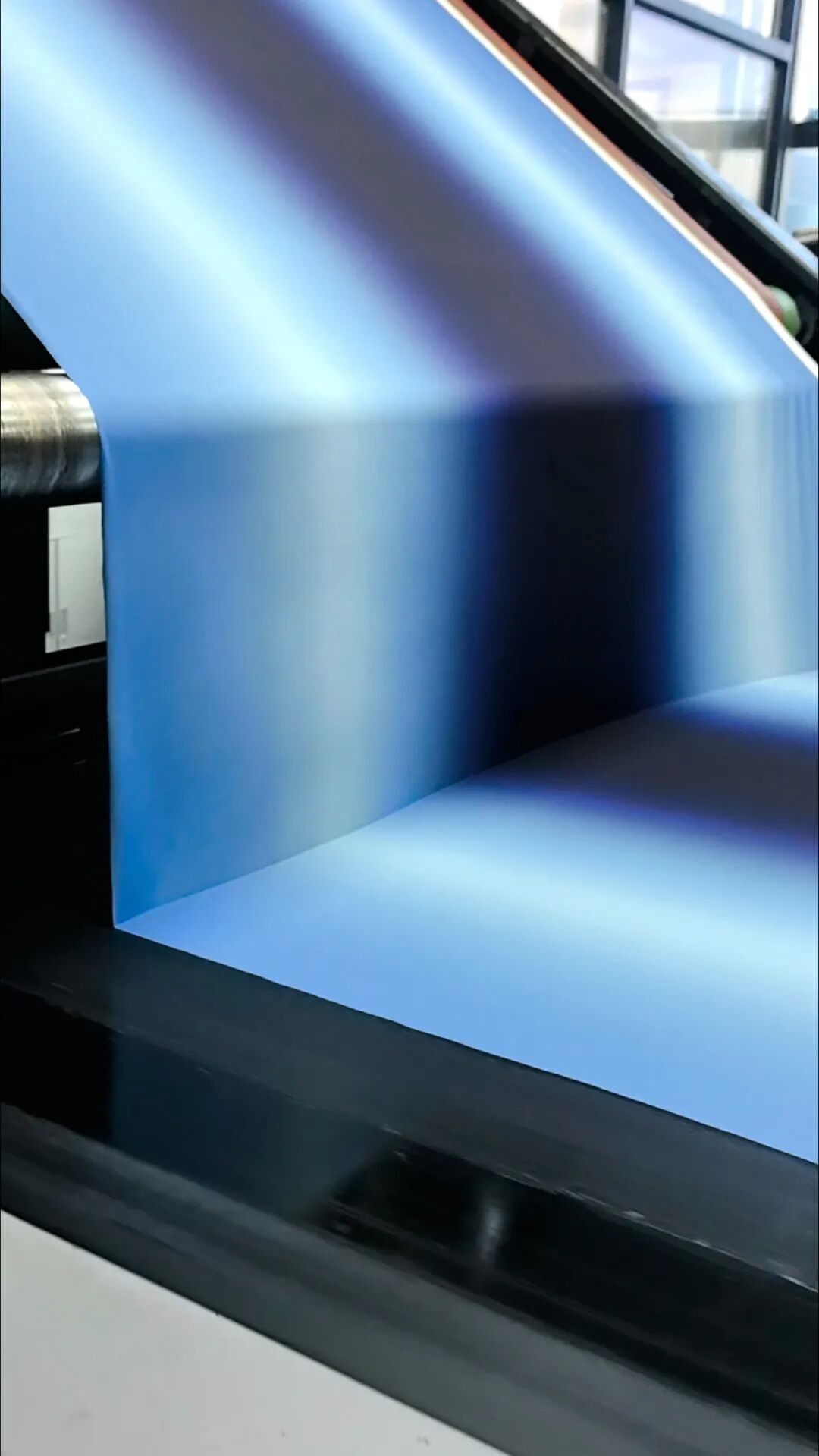

The GEEHONG ROCKET solves these challenges with two core technological innovations that work in tandem to tame the most difficult fabrics.

1. Online Wet Sizing for Superior Color & Fabric Care The ROCKET’s integrated "Online Sizing" module is a game-changer. By applying pre-treatment just moments before printing, the fabric enters the print unit in a consistently and uniformly moist state. This improves ink adhesion and penetration, delivering more vibrant color saturation and silky-smooth gradient transitions.

This continuous process also eliminates the need for a separate sizing stage, reducing fabric handling and stress. For high-end materials that demand a soft touch, like premium knits and silks, this is a critical advantage for preserving the fabric's original quality.

2. Ultra-Low Tension Control for High-Speed Stability In high-speed printing, tension is the most critical variable. GEEHONG's core Single Pass technology features a high-precision tension control system that allows highly elastic fabric to run at an extremely low, stable tension—even at speeds of 70m/min or more. The ROCKET makes the four-way stretch fabric behave with the stability of a woven material, which is the cornerstone of its ability to produce flawless prints without stretching or distortion.

The Impact: Unlocking New Opportunities in High-End Fashion

With the GEEHONG ROCKET, print factories can now confidently accept complex orders they once had to refuse. Brand designers are no longer forced to compromise their creativity by avoiding gradients or fine details on stretch fabrics.

The ROCKET’s high-precision capability makes full-coverage gradients, fine stripes, and intricate patterns a commercial reality. This opens the door for designers to create complex, seamless, full-body prints on products like athletic wear, swimwear, and bodysuits, turning the ROCKET into a powerful tool for creating high-value, best-selling products.

Company :Shenzhen Hanglory Digital Printing Group Co., Ltd

Phone:0755-23080896 / 0755-23062862

Fax:0755-23217841

Address:HanGlory Headquarters (No. 28, Gaoke Avenue, Baolong Subdistrict, Longgang District, Shenzhen, China)

E-mail :info@hanglorygroup.com

Are you ready? Then contact us